The lathe machine is also called the mother of all the machine tools. This machine is one of the most widely used machine tools all over the world and it is very versatile.

Functions of Lathe Machine

The main function of the lathe machine is to remove the material from the workpiece to get the desired size and shape. This desired shape is accomplished by holding the workpiece into the machine and then turning this particular part against the tool which removes the material from the workplace. In order to cut the material properly, the tool used should be harder and more rigid.

Types of Lathe Machine

There are many types of lathe machines and these are manufactured in a variety of types and sizes from very small to huge ones. But the principle of operation and function of all kinds of lathe machines are the same.

The different types of lathe machines are

1.) Speed Lathe

- Wood Working

- Centring

- Polishing

- Spinning

2.) Engine Lathe

- Belt Drive

- Individual Motor Drive

- Gear Drive

3.) Bench Lathe

4.) Tool Room Lathe

5.) Capstan and Turret Lathe

6.) Special Purpose Lathe

- Wheel Lathe

- Gap Bed Lathe

- T-Lathe

- Duplicating Lathe

7.) Automatic Lathe

Size of Lathe Machine

The size of the lathe machine is described by the following terms:

- The length of the bed indicates the approximate floor space occupied by the lathe machine.

- The maximum bar diameter is the maximum diameter of bar stock that will pass through the hole of the headstock spindle.

- The height of the centres was measured from the lathe bed.

- The length between centres is the maximum length of the workpiece that can be mounted between these two centres.

There are many more important terms to specify like the width of the bed and width of GAP, depth of the bed, spindle diameter, number of feeds etc.

Looking for more information then go to Wikipedia

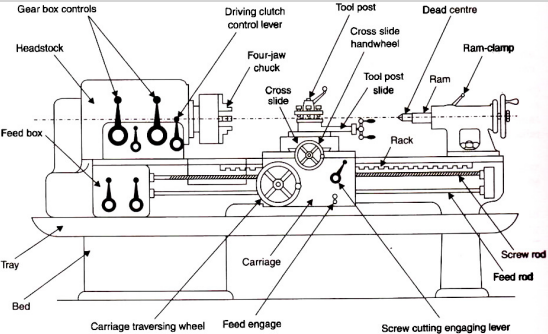

Parts of Lathe Machine

The lathe machine consists of the following principal parts:

- Bed

- Headstock

- Tailstock

- Carriage

- Feed mechanism

- Screw cutting mechanism

1.) Bed

The late bed is the base of the machine and tailstock and headstock are mountain on the lathe bed and the carriage rests on the lathe bed.

On the top of the bed, there are two sets of guideways or slides.

- Outer guideways

- Inner guideways

Outer guideways that way generally provide the sliding surface and bearing for the carriage and inner guideways are for the tailstock

There are many types of lathe bedways which are described below:

- Inverted V-bedways

- Flat bedways

- Rack

- Box Section

- Flat bedways for saddle

- The inverted-V type guideways generally provide a better guide for carriage and tailstock.

- The guide base of the lathe machine maybe inverted be or flat having an included angle of 90 degree

- The bed material should be of high compressor strength and it should also be your wear resistance and can absorb the vibrations too. It is made of the material cast iron or an alloy with cast iron, nickel and chromium.

2.) Headstock

The headstock is permanently mounted on the inner ways of the lathe and it is on the left-hand side and provides the rotating of the workplace at multiple speeds.

The headstock is generally made of carbon or nickel Chrome steel and they have a larger diameter so that it could avoid bending and should be perfectly aligned for the accurate machining of the workplace.

There are two types of spindle noses, one is called the threaded nose which carries that chuck, driving plate and faceplate and the other one is the flanged nose.

3.) Tailstock

The tailstock is located on the inner ways at the right side of the lathe machine.

Tailstock has multiple uses which are described below :

- Tailstock supports the other end of the workpiece when it is being machined between the two centres.

- The tailstock is used to hold the tool while performing operations like reaming, drilling, tapping, and boring.

- There are graduated spindles and dials on the handwheel that are used for the accurate length setting.

- The upper casting of the body can be moved away from the operator by means of offsetting the tailstock for taper turning.

4.) Carriage

The carriage consists of many parts that are used to move, control and support the cutting tool. The parts are given below:

- Saddle

- Cross Slide

- Toolpost

- Compound slide

- Apron

Saddle

A saddle is H- shaped casting that is fitted on the bed and slide alongs the way and it carries the cross slide and tool post. There are some attachments that are provided for locking the saddle to prevent the moment when any operations are carried out.

Cross Slide

A Cross slide is attached to the saddle at the right angles to the central axis of the lathe machine. It carries the tool post and compound slide.

Compound Slide

The compound’s slide is mounted on the top of the cross slide and it is used for obtaining the short tapers and angular cuts. The compound slide handle is also equipped with a micrometre dial that is used to measure the depth of the cut.

Toolpost

The tool post is located on the top of the compound rest to hold the tool. Following are the common types of tool posts.

- Single screw tool post

- Open side tool post

- Four Bolt tool post

- Four-way tool post

Apron

The apron is located on the saddle and Hangs over the front of the bed. It contains gears, and clutches, lever powerfeeds.

5.) Feed Mechanism

The feed mechanism is used for various tools. It consists of a feed reverse gear, change gear, feed gearbox, lead screw, feed rod and half nut mechanism.

6.) Screw Cutting Mechanism

With the help of a screw-cutting mechanism, a lathe machine can cut the screw in the workpiece.

Lathe Accessories

There are a lot of accessories that are attached to the lathe machine:

- Centres

- Catch Plate

- Chucks

- Faceplates

- Collets

- Mandrels and Rests

These accessories are used to hold or support the workpiece while operating. These attachments are used for some kind of specific purposes like grinding, cutting, milling, turning etc.

Lathe Operations

A lot of operations are being carried out which are given below:

- Straight Turning

- Shoulder Turning

- Chamfering

- Thread Turning

- Facing

- Knurling

- Filing

- Taper Turning

- Eccentric Turning

- Polishing

- Grooving

- Spinning

- Forming

- Boring

What is a lathe machine used for?

Lathe machine is used to carry out many operations on the workpiece such as Reaming, Boring, Turning, Drilling, Chamfering etc.

What are the types of lathe?

There are many types of lathe machines. That is

1.) Speed Lathe

2.) Engine Lathe

3.) Bench Lathe

4.) Tool Room Lathe

5.) Capstan and Turret Lathe

6.) Special Purpose Lathe

Also, Read Pressure Relief Valve Working, Types, Parts