In today’s fast-paced manufacturing and industrial maintenance environment, ensuring the right inventory is available at the right time is critical. A well-configured Computerized Maintenance Management System (CMMS) dashboard can provide real-time visibility into spare parts stock levels, turnover rates, and stockout situations, empowering maintenance teams to make data-driven decisions that minimize downtime and optimize costs.

This comprehensive guide will walk you through setting up a basic but highly effective dashboard in your CMMS that tracks these crucial inventory KPIs. The article is designed to help facilities managers, maintenance planners, and operations leaders improve inventory control, reduce stockouts, and enhance productivity.

What is a CMMS Inventory Dashboard?

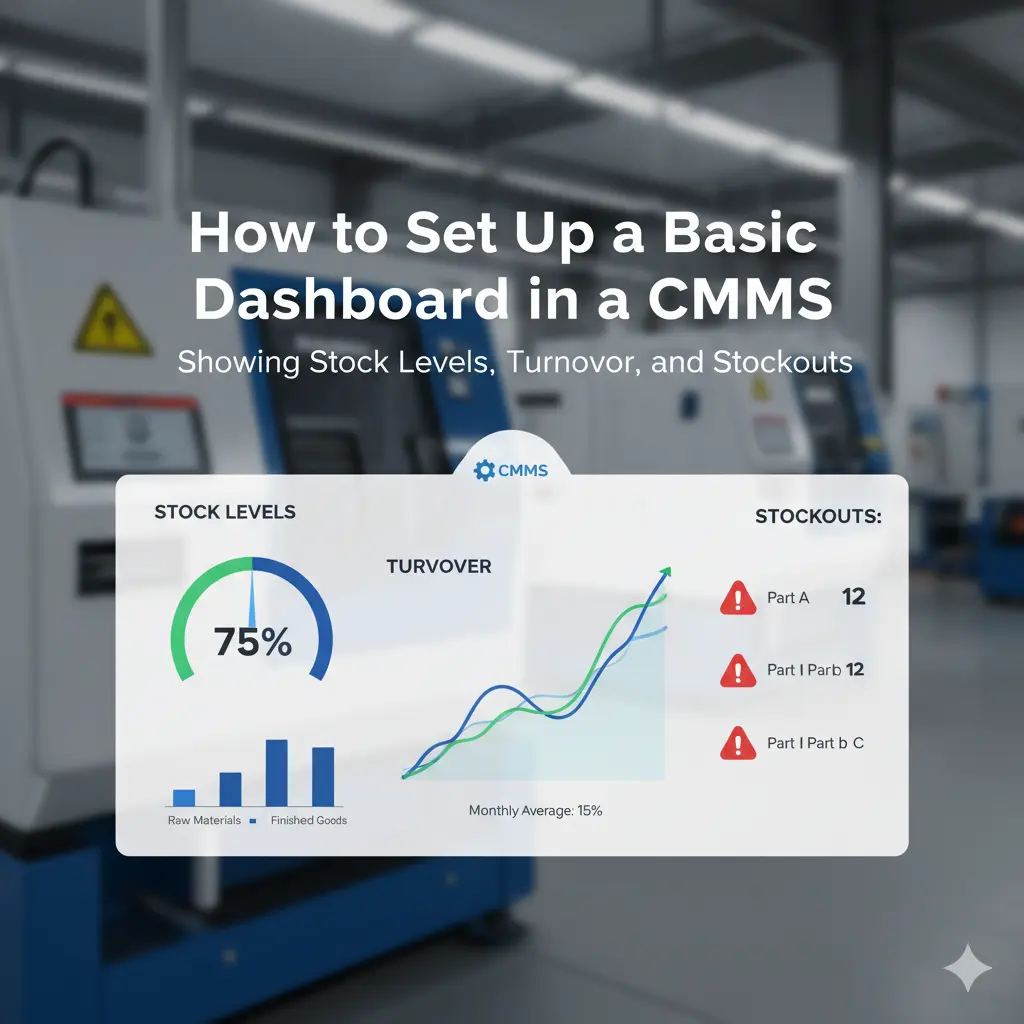

A CMMS inventory dashboard is an integrated visual interface that aggregates and displays key metrics related to your maintenance spare parts inventory. It provides a holistic view of current stock quantities, usage rates, and supply chain gaps like stockouts or backorders, all in one place.

Why Inventory Dashboards Matter

Traditional inventory management methods such as spreadsheets or siloed software often fail to provide the nuanced, real-time insight needed for proactive maintenance. A CMMS dashboard:

- Helps avoid costly downtime by forecasting stock needs

- Alerts when parts reach reorder points to streamline procurement

- Tracks part turnover to identify slow-moving and fast-moving items

- Provides transparency to maintenance and procurement teams

- Enables informed budget and stocking decisions with data-backed KPIs

Key Metrics to Display on Your CMMS Dashboard

To set up a useful dashboard, focus on these three key inventory metrics:

1. Stock Levels

Shows current on-hand quantities of each spare part and raw material. Should include:

- Available stock: quantity immediately accessible

- Reserved stock: parts allocated to work orders/not yet used

- On-order stock: incoming purchase orders not yet received

Setting minimum and maximum stock thresholds for each part helps highlight understock and overstock situations directly on the dashboard.

2. Stock Turnover Rate

Measures how often inventory cycles through in a given period, calculated approximately as:

Turnover Rate = Cost of Goods Used \ Average Inventory Value

High turnover indicates fast-moving parts requiring efficient replenishment; low turnover may signal excess or obsolete inventory needing review.

3. Stockouts and Backorders

Tracks the frequency and volume of parts that were requested but unavailable (stockouts), and backordered items due to supplier delays. Visible stockout trends help prioritize procurement and negotiate vendor SLAs.

Step-by-Step Guide to Set Up Your CMMS Inventory Dashboard

Step 1: Define Objectives and Stakeholders

Identify who will use the dashboard and what decisions it should support. Common users include maintenance planners, storeroom managers, and procurement staff.

Step 2: Clean and Organize Inventory Data

For accuracy, your inventory master data must be clean and comprehensive. Record:

- Part numbers and descriptions

- Stock locations and bin identifiers

- Minimum/maximum stock and reorder levels

- Supplier information and lead times

- Part categories (e.g., mechanical, electrical)

If migrating from spreadsheets or legacy systems, ensure duplicate and obsolete parts are purged, and naming conventions are standardized.

Step 3: Leverage CMMS Inventory Management Module

Most modern CMMS platforms support integrated inventory management with modules to:

- Register and categorize parts

- Set reorder points and safety stock

- Record stock movements linked to maintenance activities

- Automatically reduce stock on work order completion

- Configure these parameters carefully to reflect your operation’s realities.

Step 4: Select or Customize Dashboard Widgets

Using your CMMS’s dashboard builder or reporting tools, create widgets/graphs for:

- Real-time stock levels by part and category

- Turnover rate charts over monthly or quarterly periods

- Lists or alerts for parts below reorder points or yielding stockouts

- Historical stockout trends for root cause analysis

Many platforms allow click-to-filter and drill-downs to part detail or linked work orders.

Step 5: Automate Data Refresh and Alerts

Set the dashboard to update in near real-time or at scheduled intervals (e.g., daily). Configure automated notifications (email, SMS, or in-app) for critical alerts like:

- Stock levels dropping below minimum

- Pending backorders exceeding thresholds

- Turnover anomalies indicating excess inventory buildup

Automation prevents manual checking and speeds response.

Step 6: Train Users and Iterate Based on Feedback

Conduct training sessions tailored to dashboard users explaining how to interpret and act on the data. Collect feedback to refine metrics, layout, and alert thresholds periodically.

Best Practices for an Effective CMMS Inventory Dashboard

- Use Visual Indicators: Employ color coding (e.g., red for stockouts) and gauge meters for quick status recognition.

- Categorize Smartly: Group parts by criticality, usage frequency, or asset type to prioritize management.

- Integrate with Procurement Systems: Sync dashboard data with purchasing for seamless reorder workflows.

- Create KPIs for Continuous Improvement: Track fill rate, order accuracy, and lead time compliance to measure supply chain health.

- Keep It Focused: Avoid dashboard clutter; highlight actionable info to prevent cognitive overload.

Example CMMS Inventory Dashboard Configuration

| Metric | Description | Visualization Type | Frequency of Update |

|---|---|---|---|

| On-Hand Stock | Current stock levels by parts and location | Bar chart with threshold lines | Daily |

| Stock Turnover | Parts turnover rate last 3 months | Line chart | Monthly |

| Stockouts | Count & value of stockouts last 6 months | Table with trend sparklines | Monthly |

| Backorders | Outstanding backordered quantities | Pie chart by supplier | Weekly |

| Critical Parts Alerts | Parts below minimum stock | List with flag icons | Real-time/As events occur |

Frequently Asked Questions (FAQs)

Q: Can I set reorder thresholds automatically?

Yes, many CMMS systems allow automatic threshold setting based on historical usage patterns and lead times.

Q: How do I integrate the dashboard with other business systems?

Most CMMS platforms support APIs or connectors to export dashboard data to ERP, procurement, or BI tools.

Q: What if my parts data is inaccurate?

Start with a master data cleanup project and standardize naming conventions to improve accuracy before relying on dashboards.

Conclusion

A well-designed CMMS inventory dashboard is an indispensable tool for modern maintenance operations. By continuously monitoring stock levels, turnover, and stockouts, you empower your facility to proactively manage spare parts, reduce emergency orders, and minimize costly downtime. Follow the steps above to set up your dashboard and begin unlocking the full value of your CMMS investment.