An Equipment Maintenance Log Book is an indispensable instrument in the management of facilities and industries area, providing a logical method of recording every maintenance job that is that is performed on equipment and machinery. This complete guide will discuss the significance of a log book for maintenance on equipment book, the key elements as well as the best way to design one, and what best practices to follow to increase its efficiency, while also adding the word “equipment maintenance logbook” strategically to boost SEO.

What is an Equipment Maintenance Log Book?

A log book for maintenance of equipment is a precise log that documents the maintenance tasks that are performed on equipment, and records crucial information such as inspection dates, dates for repairs, the parts that were replaced, the technicians involved, and other observations regarding the condition of equipment. The goal of the maintenance log book for equipment is to create an organized archive of maintenance work, which allows maintenance and facility managers to enhance asset reliability decrease downtime and prolong the lifespan of costly equipment.

Importance of an Equipment Maintenance Log Book

The log book for maintenance of equipment is essential for businesses seeking to improve their efficiency and ensure compliance with regulatory requirements. Through meticulously recording maintenance activities firms can identify frequent issues and plan preventive maintenance and make informed choices about the repair or replacement of equipment to avoid costly downtime and urgent repairs. Furthermore, a maintenance log book helps ensure conformity with safety regulations and industry standards by providing valid evidence when audits are conducted.

Key Components of an Equipment Maintenance Log Book

A well-organized maintenance log for equipment book will typically include the following elements essential to a good book:

- Equipment identification: Unique identifiers such as serial number or model, manufacturer and physical address to differentiate assets and simplify tracking.

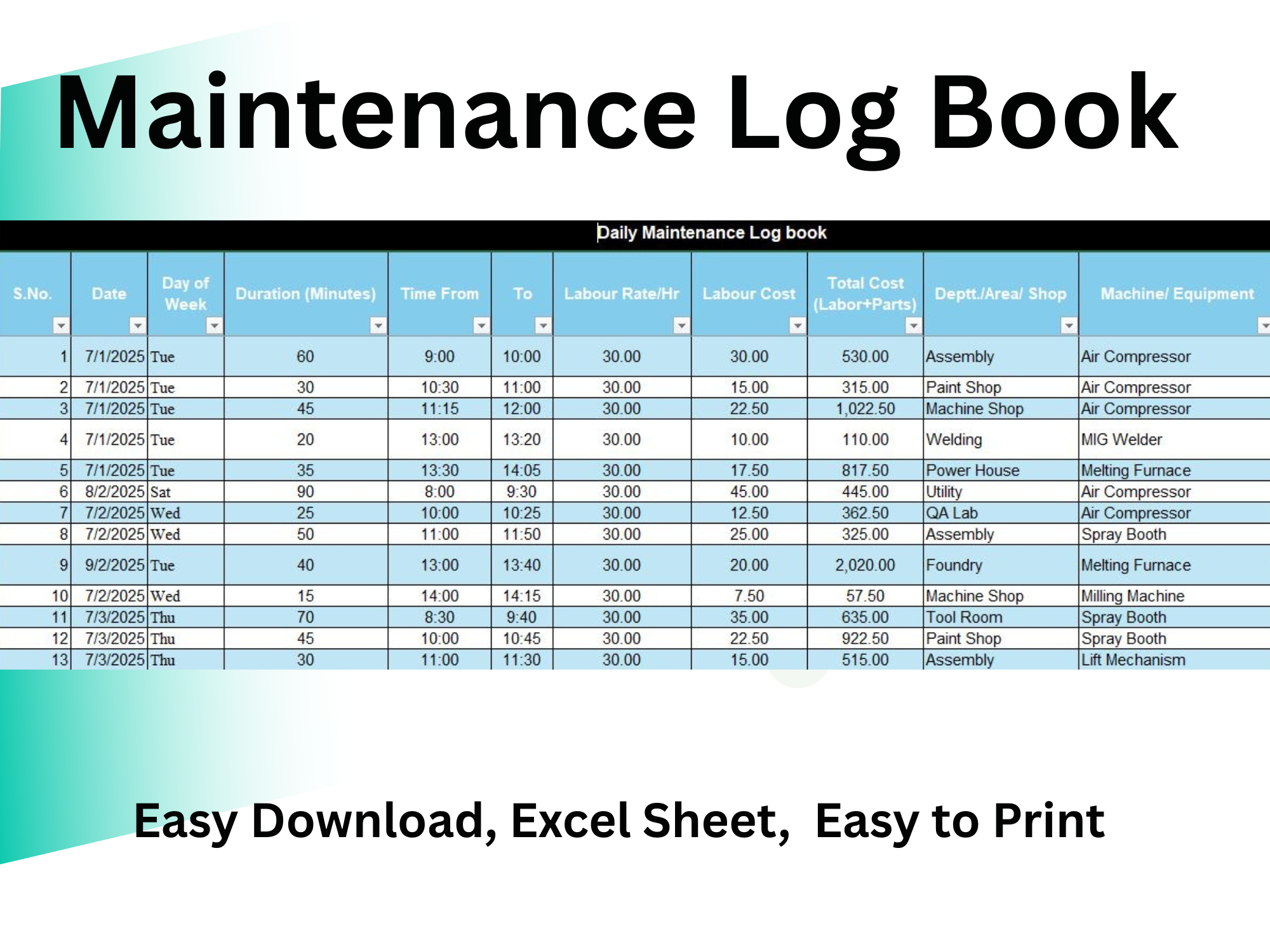

- Maintenance Information: Dates of maintenance and detailed descriptions of the work carried out, the replacement or repair of components repaired, and comments about the condition of equipment prior to and following the task.

- Tech Information Identification numbers or names of those responsible for maintenance work, which encourages accountability and transparent communication.

- Maintenance History and schedule: Documentation of past maintenance as well as upcoming scheduled tasks to ensure prompt maintenance and prevent service from being missed.

- Cost Record: Expenses related to maintenance components, labor, and parts to assess maintenance budgets and cost-effectiveness.

These elements make up the maintenance log book for equipment an essential resource for managing the whole life cycle of equipment in the facility.

How to Create an Effective Equipment Maintenance Log Book

The creation of a successful maintenance log book requires an organized approach to record the relevant details:

- Listing All Equipment Completely list all the assets that need to be tracked with the identifying information so that you don’t cause confusion.

- Create Log Fields Create fields that record crucial information such as the equipment’s specifications and dates for service maintenance descriptions, details of technicians and the parts that are that are used.

- Utilize Standardized Formats whether digital or physical, the need for standardization is vital to ensure consistency and ease of cross-referencing.

- Schedule Maintenance Integrate preventive maintenance programs to ensure timely inspections and servicing.

- Trainers: Assuring that team members are aware of how to correctly complete the maintenance log book and understand its significance to the operation’s achievement.

- Make use of digital tools: Transition to digital maintenance log books for equipment, which are connected to the CMMS (Computerized Maintenance Management Systems) to automate reminders, minimize errors, and provide remote access.

Best Practices for Using an Equipment Maintenance Log Book

- Keep It Up-to-date: Maintenance logs should be updated immediately following any maintenance activity in order to ensure exactness and completeness.

- Regular review and auditing: Periodically audit the maintenance log book for your equipment to find gaps, frequent issues, and areas of improvement.

- Make sure that the log book is accessible: Make the equipment maintenance log book available to everyone involved to promote collaboration and prompt intervention.

- Specific Note-taking: Instruct technicians take note of specific details and irregularities in order to aid in diagnosing future issues more efficiently.

- Integration with Integrate with Asset Management: Tie the maintenance log book for the equipment to more general asset management strategies to boost the efficiency of your business and ensure that you have a lifecycle management plan.

Benefits of an Equipment Maintenance Log Book

Utilizing a maintenance log for equipment book can provide many benefits:

- Improved Equipment Reliability Retaining machine performance with periodic inspections and timely intervention.

- Cost savings: Prevents expensive breakdowns and maximizes inventory of parts with exact maintenance monitoring.

- enhanced safety: Ensures compliance with maintenance guidelines that safeguard workers and equipment.

- Data-driven decisions: Makes it possible to make educated decisions based on maintenance history and trends that are documented in the maintenance log of equipment book.

- Legal compliance: Serves as proof of regular maintenance, which is in compliance with the requirements of insurance and regulatory agencies.

In the end, a maintenance logbook is an essential documentation tool that aids maintenance teams in providing consistently high-quality, quality equipment care. By keeping accurate, detailed and current documents of all maintenance tasks business can increase the efficiency of their operations, decrease costs, and increase security. For those who manage facilities or industrial equipment spending time creating and managing a proper maintenance log book for equipment is vital to long-term success as well as regulatory compliance.

This thorough understanding and the implementation of the maintenance log book for equipment can help you manage the lifecycle of your equipment and create a proactive maintenance culture in your company.