What if your factory could run like a well-oiled machine—fewer breakdowns, lower costs, and maximum output—starting tomorrow? Artificial intelligence (AI) is turning this dream into reality! Factories worldwide grapple with unexpected downtime, soaring repair bills, and inefficient processes. But AI is revolutionizing maintenance for mechanical and electrical systems, making factories smarter and more efficient.

In this article, we’ll share seven AI-powered hacks to transform your factory’s performance overnight. From predicting equipment failures to slashing energy costs, these tips are practical and ready to implement. Let’s unlock the power of AI and boost your factory’s efficiency!

Also Check Can AI-Powered Chatbots Revolutionize Equipment Maintenance?

Why AI Is a Game-Changer for Factory Maintenance

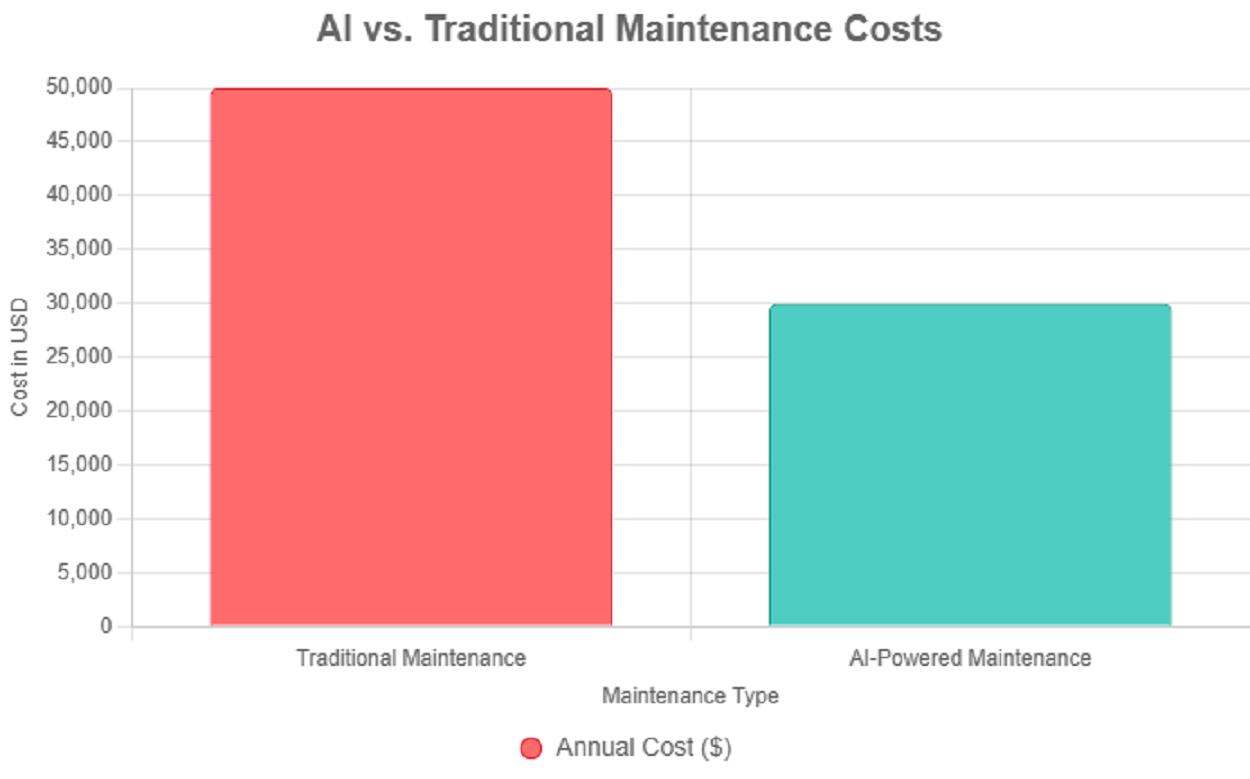

AI is reshaping industrial maintenance by leveraging machine learning, IoT sensors, and real-time analytics. It predicts failures, optimizes schedules, and reduces costs. A 2023 McKinsey report states that AI-driven predictive maintenance can cut costs by 25-30% and reduce downtime by up to 45% [1]. This means more uptime and bigger profits.

Unlike traditional reactive maintenance, AI proactively identifies issues before they escalate. For mechanical and electrical systems, this translates to fewer disruptions and smarter resource use. Whether you run a small workshop or a large plant, AI is your key to staying competitive.

Hack #1: Monitor Equipment in Real Time with AI

Unexpected breakdowns can halt production. AI-powered real-time monitoring uses IoT sensors to track metrics like vibration, temperature, and pressure. Platforms like General Electric’s Predix analyze this data instantly, alerting you to anomalies before they cause failures [2].

This hack keeps your factory running smoothly. For example, a faulty bearing can be flagged early, preventing a costly shutdown. Install IoT sensors on critical machinery and connect them to an AI platform like Predix or Siemens MindSphere, many of which offer free trials.

Actionable Tip: Start with high-value equipment and check AI dashboards daily for insights.

Hack #2: Predict Failures with Machine Learning

Why fix machines after they break? Machine learning models predict failures by analyzing historical data, usage patterns, and environmental factors. IBM Maximo’s predictive maintenance module, for instance, forecasts equipment issues with up to 90% accuracy, per IBM’s case studies [3].

This hack saves time and money by scheduling repairs proactively. A predicted pump failure can be addressed during planned downtime, avoiding production losses. Start by integrating a cloud-based AI tool with your maintenance logs.

Actionable Tip: Upload equipment data to an AI platform and review predictive reports weekly.

Hack #3: Optimize Maintenance Schedules with AI

Fixed maintenance schedules waste time and money—servicing too early is inefficient, while delays risk breakdowns. AI tools like UpKeep create dynamic schedules based on real-time equipment data, prioritizing high-risk machines [4].

This hack reduces unnecessary maintenance. For example, AI might show a motor needs servicing every 8 months, not 4, saving resources. Connect your equipment data to an AI scheduling tool and review its recommendations weekly.

Actionable Tip: Analyze usage patterns with AI to adjust maintenance intervals for one machine type.

Hack #4: Automate Inspections with AI-Powered Drones

Inspecting tall structures or hazardous areas is slow and risky. AI-powered drones, like Skydio’s, use advanced vision systems to scan equipment for wear, corrosion, or damage, processing images in real time [5].

This hack saves time and improves safety. A drone can inspect a factory’s electrical grid or turbines in minutes, flagging issues instantly. Pilot a drone inspection program for critical areas to see immediate results.

Actionable Tip: Rent an AI-enabled drone for a trial to assess inspection efficiency.

Hack #5: Enhance Electrical Systems with AI Diagnostics

Electrical failures can grind production to a halt. AI diagnostic tools, like Fluke’s thermal imaging cameras with AI analytics, detect faults by analyzing current, voltage, and heat signatures [6]. They can spot overheating circuits before they cause outages or fires.

This hack minimizes downtime and repair costs. Train your electricians to use AI tools during routine checks to catch issues early. Many devices are intuitive, requiring minimal training.

Actionable Tip: Use an AI-powered thermal camera weekly to scan electrical panels.

Hack #6: Boost Energy Efficiency with AI

Energy costs are a major expense, but AI can cut them significantly. Schneider Electric’s EcoStruxure platform uses AI to monitor and optimize energy use in real time, adjusting systems like motors or HVAC for efficiency [7]. Studies show AI can reduce energy costs by 15-20%.

This hack delivers quick savings. Start by monitoring high-energy equipment like compressors. The results will show up on your utility bill fast.

Actionable Tip: Install an AI energy management system and review monthly reports for savings.y

Hack #7: Train Your Team with AI Simulations

Training technicians on complex machinery is costly and risky. AI-powered virtual simulations, like Bosch Rexroth’s training platforms, create realistic repair scenarios, adapting to real-world challenges [8]. Technicians practice without touching live equipment.

This hack boosts skills and reduces errors. Invest in VR-based AI training for critical systems to see your team’s performance soar. Affordable subscriptions make this accessible for small factories.

Actionable Tip: Try a free demo of an AI training simulator to evaluate its impact.

How to Get Started with AI in Your Factory

Ready to harness AI? Here’s how:

- Identify Pain Points: Pinpoint issues like frequent breakdowns or high energy costs.

- Select a Tool: Try a user-friendly platform like IBM Maximo or UpKeep, many with free trials.

- Train Staff: Spend a week training your team on the AI tool’s basics.

- Track Results: Run a 30-day pilot and scale up based on success.

AI tools are more affordable than ever, with cloud-based options starting at low monthly fees. Even small factories can see quick wins with one AI hack.

Conclusion

AI is transforming factory maintenance, and these seven hacks—real-time monitoring, predictive analytics, optimized schedules, drone inspections, electrical diagnostics, energy efficiency, and AI training—can boost your efficiency overnight. Pick one, like predictive maintenance, and start today. Your factory will thank you with less downtime and bigger savings.

Which hack are you excited to try? Share your thoughts or AI experiences in the comments below! For more tips, visit mechtrician.com and take your factory to the next level.

References

- McKinsey & Company. (2023). “The potential of AI in manufacturing.” https://www.mckinsey.com/business-functions/operations/our-insights/the-potential-of-ai-in-manufacturing

- GE Digital. (2024). “Predix Platform Overview.” https://www.ge.com/digital/product/predix-platform

- IBM. (2024). “Maximo Asset Management.” https://www.ibm.com/products/maximo

- UpKeep. (2024). “AI-Powered Maintenance Management.” https://www.upkeep.com/features/ai-maintenance

- Skydio. (2024). “Industrial Inspection Solutions.” https://www.skydio.com/industries/inspection

- Fluke Corporation. (2024). “AI-Enhanced Thermal Imaging.” https://www.fluke.com/en-us/products/thermal-imaging

- Schneider Electric. (2024). “EcoStruxure for Industry.” https://www.se.com/us/en/work/solutions/for-business/industry

- Bosch Rexroth. (2024). “Training Systems with AI.” https://www.boschrexroth.com/en/us/training