What are Different Types of Threads

Before discussing the different types of threads, let’s understand the threads. There are many things around us that are connected with the help of thread. The very first fasting part with threads was used in ancient Rome. At the beginning of the 17th century, the thread connection appeared similar to that we used today. Initially, the thread was only in inches but then the French introduced a metric thread at the beginning of the 19th century.

What is a Screw Thread?

A thread is a surface that is formed by the helical movement of the flat contour along the helical line. We can also say that a thread is a continuous helical ridge formed on the outside or inside of a cylindrical surface. There are many types of threads.

If a screw is having a single helical groove along the body of the cylinder is called single-threaded and if a second thread is there in the spaces of the first along the body of the cylinder then it is called double-threaded. Similarly, triple and quadruple threads can be formed. These are also called multi-threads. The screws that are cut can be of either right hand or left hand and it depends on the application where we use it.

Screwed joints consist of nuts and bolts. These are used when we have to quickly Mount and dismount the machine parts so that they can be easily assembled or dissembled.

Thread Parameters

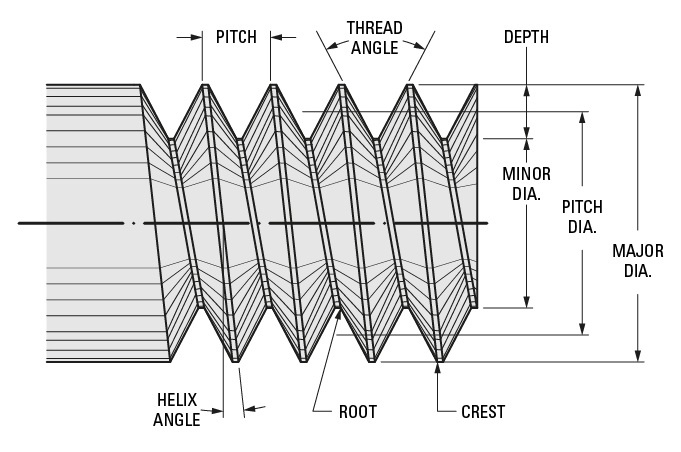

There are terms associated with the screw threads which are important to know and described below.

Major Diameter

Major diameter is defined as the largest diameter of any internal or external screw threads. For external threads, the major diameter is the outside diameter and for inner threads, the major diameter is the inner diameter of the threads. It is also called the nominal or outside diameter.

Minor diameter

Minor diameter is defined as the smallest diameter of any internal external screw threads. For external threads, the minor diameter is the inner thread diameter and for internal threads, the minor diameter is the outer thread diameter. Minor diameter is sometimes called route or called the diameter.

Pitch diameter

Pitch diameter is also known as effective diameter. Pitch diameter is defined as the imaginary diameter on a cylindrical screw thread, which will pass through at such points to make the equal width of spaces and width of threads. It is the most probable area of external and internal threads engaging.

Pitch

Pitch is defined as the distance from point of one thread to the corresponding point of the next thread. The pitch is measured in millimeters and mathematically, it can be defined as

Pitch = 1/number of threads per unit length of the screw

Thread per inch (TPI)

Thread per inch is defined as the number of threads in a distance of 1″ along the axis or length of the threads in the same axial plane on one side of the axis of rotation. It is the main and common parameter of all kinds of threads.

Lead

Lead is defined as a distance between the two corresponding points on the same helix. In the case of single start threads, the pitch is equal to the lead and in the case of double start, it is twice the pitch and thrice the pitch in triple star and so on.

Helix Angle

The helix angle is the angle between a line parallel to the axis of rotation and the helix of the thread. Mathematically, Helix angle is defined as:

φ= arctan (P/π×Dpitch )

Where φ= Helix angle

L = Thread pitch

dm = Pitch diameter

π ≈ 3.142

Lead Angle

Lead angle is defined as the angle between the plane of rotation and the helix of the thread. Mathematically, it can be written as:

φL= arctan (Lead/π×Dpitch )

Lead= n×P

Where:

φL = Lead angle

Dpitch = Pitch diameter

P = Thread pitch

n = Number of thread starts

π ≈ 3.142

Crest

The top part or top surface of the thread is called the crest.

Root

The root is the bottom surface of the thread that is formed by the adjacent flank of the screw.

Flank

The surface that connects the root and crest is called a flank.

Classification of Threads

Different types of threads can be classified as below:

- Classification based on Gender

- Internal Thread

- External Thread

- Classification based on Designation

- Connection

- Sealing

- Fastening

- Special

- Motion

- Classification based on Handedness

- Internal Thread

- External Thread

- Classification based on Pitch

- Coarse Pitch

- Fine Pitch

- Classification based on Profile

- Trapezoidal

- Round

- Triangular

- Scalene

- Square

- Classification based on Start

- Single-Start

- Multi-Start

- Classification based on Surface Shape

- Cylindrical

- Conical

Different Types of Threads

There are many different types of screw threads which are defined below:

1. British standard Whitworth (B.S.W.) thread

British standard Whitworth thread or BSW threads have coarse pitches and has symmetrical v thread in which the angles between flanks is 55 degree. These threads are usually found on the bolts and screwed fastening for special functions.

The British standard Whitworth threads with the fine pitches are used where the greatest strength of the root is required.

2. British Association (B.A.) thread

This is a British standard Whitworth thread with fine pitches. These threads are used for instrumentation and other precision works.

3. American national standard thread

The American National standard threads have a flat crest and roots and because of the flat shape, they can be used roughly. These threads are used for general purposes for example on nuts, screws, bolts, etc.

4. Square thread

Square threads have their crest and roots flat and the shape of a square. The pitch is often twice as of B.S.W threads of the same diameter. Square threads are of very high efficiency and used in the translation of power in either direction. These kinds of threads are used in machine tools, valves, projects, etc but square threads are not as strong as that of V-threads.

5. Knuckle thread

Knuckle threads are also the modification of the square thread. In this case, it has a rounded top and bottom. These threads are used for and can be found on railway carriage couplings, and hydrants and used in electrical trades.

6. Buttress thread

Buttress threads have the advantage of both square and V threads. It has low frictional resistance characteristics and is used for transmission of power in one direction only.

7. Metric thread

Metric thread is an Indian standard thread and is similar to B.S.W threads. It has an included angle of 60 degrees.

8. Unified standard thread

In this case, the 3 countries great Britain, Canada, and United States come to an agreement that they will form a common thread so that they can exchange machinery. In unified standard threads, the screw thread system is having an included angle of 60 degrees. These threads have rounded roots and crest.

9. Acme thread

Acme thread is a modification of the square thread and it is much stronger than the square threads. Acme threads are generally used in screw-cutting lathes, bench vice, etc.

FAQs

What is a screw thread?

A thread is a surface that is formed by the helical movement of the flat contour along the helical line.

If you have any queries related to different types of threads, kindly comment down below.

Also Read, Types of Engines and their explanation