Threads Per Inch (TPI) is a critical measurement in many industries, from manufacturing to textiles, plumbing, and even DIY projects. Whether you’re dealing with screws, bolts, or threads in fabrics, understanding TPI ensures compatibility, precision, and durability. In this comprehensive guide, we’ll delve into what TPI is, why it matters, and how to measure it effectively.

What is Threads Per Inch (TPI)?

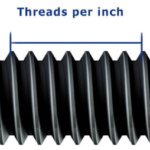

Threads Per Inch, commonly abbreviated as TPI, refers to the number of threads counted along a one-inch length of a threaded object, such as a screw, bolt, or pipe. It is a standard measurement used to determine the coarseness or fineness of threads.

- Fine Threads: Higher TPI, with more threads packed into an inch. These threads are often used in applications where precision and detail are critical, such as in aerospace or automotive industries. Fine threads also provide better resistance to vibration and can offer a tighter seal.

- Coarse Threads: Lower TPI, with fewer threads per inch. Coarse threads are easier to manufacture and assemble, making them ideal for heavy-duty applications like construction, plumbing, and woodworking. They are less prone to stripping and can handle higher loads compared to fine threads.

Understanding the distinction between fine and coarse threads helps in selecting the right component for the task at hand, ensuring both functionality and durability.

Why is TPI Important?

TPI impacts the performance, strength, and application of threaded components. Here are a few reasons why TPI matters:

- Compatibility: Ensures that screws, bolts, or pipes fit perfectly with their counterparts. Using the wrong TPI can lead to mismatched components, causing mechanical failures or leaks in plumbing systems.

- Strength: Coarse threads (low TPI) are typically stronger and better suited for heavy-duty applications, such as holding together large structures or machinery. Fine threads (high TPI), on the other hand, provide higher tensile strength and are used in precision applications where exact alignment is critical.

- Application-Specific: Different industries require specific TPI standards for optimal performance. For example, plumbing threads must meet specific standards like NPT or BSP to ensure a leak-proof seal, while industrial bolts may follow ISO or ASTM standards.

- Durability and Wear Resistance: Fine threads distribute stress over a greater surface area, reducing wear and tear. Coarse threads are better suited for materials prone to damage or in environments with frequent assembly and disassembly.

How to Measure TPI

Measuring TPI accurately is essential to avoid mismatched components. Here’s a step-by-step guide:

Tools Needed:

- Thread Gauge: A specialized tool for measuring threads.

- Ruler or Caliper: For measuring thread length and diameter.

- Magnifying Glass: Optional, for inspecting fine threads.

Steps:

- Prepare the Object: Clean the threads to remove dirt or debris that could obscure the measurement.

- Use the Thread Gauge: Align the threaded object with the notches or ridges on the gauge. Ensure the threads fit snugly without gaps.

- Count the Threads: For a manual method, count the number of threads along a one-inch length using a ruler or caliper. If the object is shorter than one inch, count the threads and divide by the length (in inches) to calculate TPI.

- Record the Measurement: Note the TPI and confirm it matches the intended specifications.

Common Challenges:

- Worn Threads: Damaged or worn threads can lead to inaccurate measurements. Always inspect the threads beforehand.

- Irregular Surfaces: Threads on curved or irregular surfaces may require additional tools or techniques for precise measurement.

- Differentiating Fine and Coarse Threads: Use a thread chart to compare measurements if unsure about the classification.

Threads Per Inch Calculator

Thread Pitch Calculator

Enter the fastener size to find the thread pitch:

Types of Threads Based on TPI

Threads are classified into two main types based on TPI:

1. Fine Threads

- Characteristics: Fine threads have more threads per inch, resulting in a smoother surface and tighter fit. They are often used in applications requiring precision and high tensile strength.

- Applications:

- Automotive and aerospace industries for components requiring exact alignment.

- Machinery and equipment where resistance to vibration is critical.

- Electronic devices and small appliances.

- Advantages:

- Improved vibration resistance.

- Higher clamping force for a given torque.

- Better sealing capabilities.

- Disadvantages:

- More prone to cross-threading during assembly.

- Requires more time to assemble due to the higher thread count.

2. Coarse Threads

- Characteristics: Coarse threads have fewer threads per inch, making them easier to manufacture and assemble. They are ideal for heavy-duty applications.

- Applications:

- Construction and woodworking for fast and reliable assembly.

- Plumbing systems, especially for pipes and fittings.

- Outdoor equipment and large machinery.

- Advantages:

- Greater resistance to stripping in softer materials.

- Faster assembly and disassembly.

- Better performance in dirty or corrosive environments.

- Disadvantages:

- Less resistance to vibration.

- Reduced clamping force compared to fine threads.

Chart: Fine vs. Coarse Threads Based on TPI

| Feature | Fine Threads (High TPI) | Coarse Threads (Low TPI) |

|---|---|---|

| Thread Count per Inch | More threads tightly packed into an inch | Fewer threads, widely spaced |

| Strength | High tensile strength but lower load-bearing capacity | Better for heavy-duty applications, higher load capacity |

| Vibration Resistance | Excellent resistance to loosening under vibration | Moderate resistance, may loosen without locking methods |

| Assembly Time | Takes longer to assemble due to higher thread count | Quicker to assemble and disassemble |

| Preferred Use Case | Precision applications like aerospace, electronics, and textiles | Heavy-duty applications like construction and plumbing |

| Wear Resistance | Distributes stress evenly over threads, reducing wear | Can strip more easily in soft materials |

| Sealing Efficiency | Provides a tighter seal, ideal for high-pressure environments | Suitable for general use, may require additional sealing |

Standard TPI for Common Fasteners

Here’s a quick reference table for standard TPI values:

Here’s a chart with 25 commonly used fastener sizes, showcasing coarse and fine threads along with typical applications:

| Fastener Size | Coarse Thread (TPI) | Fine Thread (TPI) | Applications |

|---|---|---|---|

| 1/4-inch | 20 | 28 | Coarse for wood screws, fine for machinery and precision equipment |

| 5/16-inch | 18 | 24 | Coarse for structural joints, fine for automotive components |

| 3/8-inch | 16 | 24 | Coarse for plumbing, fine for aerospace parts |

| 7/16-inch | 14 | 20 | Coarse for construction, fine for industrial machinery |

| 1/2-inch | 13 | 20 | Coarse for heavy construction, fine for automotive suspension |

| 9/16-inch | 12 | 18 | Coarse for pipelines, fine for precision tools |

| 5/8-inch | 11 | 18 | Coarse for bridge assembly, fine for mechanical systems |

| 3/4-inch | 10 | 16 | Coarse for large-scale construction, fine for industrial machinery |

| 7/8-inch | 9 | 14 | Coarse for oil rigs, fine for engine components |

| 1-inch | 8 | 12 | Coarse for heavy equipment, fine for aircraft parts |

| 1-1/8-inch | 7 | 12 | Coarse for steel frameworks, fine for engineering assemblies |

| 1-1/4-inch | 7 | 12 | Coarse for pipelines, fine for high-pressure systems |

| 1-3/8-inch | 6 | 12 | Coarse for construction machinery, fine for industrial piping |

| 1-1/2-inch | 6 | 12 | Coarse for bridges, fine for aerospace systems |

| 1-5/8-inch | 5 | 11 | Coarse for shipbuilding, fine for specialized equipment |

| 1-3/4-inch | 5 | 11 | Coarse for mining equipment, fine for heavy industrial uses |

| 2-inch | 4.5 | 8 | Coarse for marine construction, fine for large machinery |

| 2-1/4-inch | 4.5 | 8 | Coarse for railway equipment, fine for hydraulic systems |

| 2-1/2-inch | 4 | 8 | Coarse for agricultural machinery, fine for power plants |

| 2-3/4-inch | 4 | 8 | Coarse for oilfield equipment, fine for military-grade components |

| 3-inch | 4 | 8 | Coarse for infrastructure projects, fine for precision engineering |

| 3-1/4-inch | 4 | 8 | Coarse for industrial scaffolding, fine for advanced robotics |

| 3-1/2-inch | 4 | 8 | Coarse for wind turbines, fine for critical aerospace applications |

| 4-inch | 4 | 8 | Coarse for dams and bridges, fine for specialized energy systems |

| 4-1/2-inch | 4 | 8 | Coarse for oil platforms, fine for high-precision mechanical assemblies |

Standardizing TPI ensures compatibility across industries and regions. For example, bolts used in automotive applications often follow fine thread standards, while construction bolts use coarse threads for ease of assembly.

TPI in Textile Threads

In the textile industry, TPI is a key factor in determining the quality and strength of fabrics and sewing threads. A higher TPI in sewing threads results in:

- Stronger Stitches: Fine threads with higher TPI create tight, durable stitches that are less likely to unravel. This is especially important in high-stress areas of garments or upholstery.

- Finer Fabrics: High TPI enhances the texture and appearance of fabrics, making them suitable for luxury garments and intricate designs.

- Specialized Applications: Threads with high TPI are used in embroidery, quilting, and other decorative stitching techniques.

Lower TPI threads, on the other hand, are used for heavy-duty stitching or coarse fabrics like denim or canvas. Choosing the right TPI ensures the durability and aesthetics of the final product.

TPI in Plumbing and Piping

TPI is equally important in plumbing applications, especially for threaded pipes and fittings. Common standards include:

- NPT (National Pipe Thread): Widely used in North America, NPT threads are tapered to create a tight seal. Typical TPI values for NPT fittings range from 11.5 to 27.

- BSP (British Standard Pipe): Used outside North America, BSP threads can be parallel or tapered. The TPI values for BSP threads vary depending on the application and pipe size.

- Metric Threads: Some plumbing systems use metric threads, which are measured in thread pitch rather than TPI.

Ensuring the correct TPI prevents leaks and ensures a secure fit. Always check the compatibility of threaded components, especially when working with international standards.

Tools for Measuring and Working with TPI

Investing in the right tools can make working with TPI easier and more accurate. Here are some commonly used tools:

- Thread Gauges: Specifically designed to measure TPI, these tools are available in both metric and imperial versions. They are essential for identifying unknown threads.

- Calipers: Used to measure the diameter of threads, ensuring they match the intended specifications.

- Thread Charts: Handy reference tools that list standard TPI values for various fasteners and fittings.

- Micrometers: For highly precise measurements, especially in fine-thread applications.

For beginners, starting with a simple thread gauge is often sufficient. Professionals may require a combination of tools for complex projects.

FAQs About TPI

1. What is the most common TPI for screws?

The most common TPI for screws varies by size and application. For example, 20 TPI is typical for 1/4-inch screws used in general-purpose applications.

2. How does TPI affect the strength of a fastener?

Coarse threads (low TPI) are generally stronger and better for heavy loads, as they engage more material. Fine threads (high TPI) provide greater tensile strength and are less likely to loosen under vibration.

3. Can I measure TPI without special tools?

Yes, you can use a ruler to measure TPI manually, but a thread gauge provides a faster and more accurate measurement.

4. What is the difference between pitch and TPI?

Pitch is the distance between adjacent threads, measured in millimeters for metric threads. TPI, on the other hand, counts the number of threads per inch in imperial systems. Both measurements describe thread spacing but are used in different standards.

Conclusion

Threads Per Inch (TPI) is a fundamental measurement in a wide range of applications, from screws and bolts to textiles and plumbing. Understanding TPI ensures precision, compatibility, and reliability in your projects. By using the right tools and techniques, you can confidently work with TPI in any industry.

If you found this guide helpful, share it with others and explore more of our detailed articles on related topics!

References: Wikipedia

1 thought on “Threads Per Inch (TPI) Chart and Calculator”