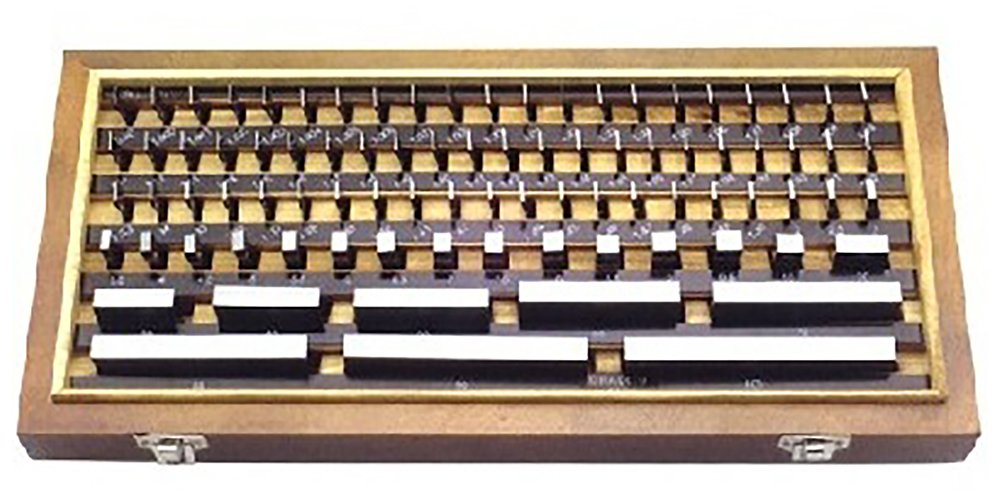

In this article, we will discuss Slip gauge and their types and uses. We have seen many instruments such as the Vernier caliper, Micrometer, and Depth gauge which are used for the measurements to a higher degree but the accuracy of these instruments depends on the accuracy of the workman involved in their manufacturing. So there are chances of errors in the measurement and measuring tools. Here we will discuss the slip gauges which are also known as Gauge blocks. These slip gauges are rectangular blocks that provide a high degree of accuracy. These gauge blocks are also known as Johansson gauges.

Types of Slip Gauges

Slip Gauges are available in the following three types:

- Rectangular Slip gauge

- Square slip gauge without a Central hole

- Square slip gauge with a Central hole

Out of these three gauges, rectangular gauges are the most widely used slip gauges because they are convenient where the space is limited and excess weight is to be avoided.

Slip gauges are classified into different grades which depend on their guaranteed accuracy. The grade defines the type of application for which it is used such as inspection, reference, or calibration. So basically slip gauges are divided into 5 grades which are given below:

- Grade 00

- Grade 0

- Grade 1

- Grade 2

- Calibration Grade

We will discuss each grade one by one.

Grade 00

Grade 00 slip gauge is kept in the standard rooms and is used for inspection or calibration of high precision only. These slip gauges are used to check the accuracy of the workshop tools and grade 1 and great 2 slip gauges.

Grade 0

Grade 0 slip gauges are used for inspection and are also called inspection grade gauge blocks which are used in the tool room and for inspection of high accuracy work. Proper care is required to guard it against rough usage.

Grade 1

Grade 1 slip gages are used in tool room applications such as setting up the sine bars, calibration of vernier caliper, micrometer instruments, and so on.

Grade 2

Grade 2 slip gauges are used in the workshops and are typically used for setting up machine tools, milling cutters, and on the shop floor.

Calibration Grade

These calibration slip gauges are of a special grade with the actual size of the slip is mentioned on the chart that is provided with the set of slip gauges. Although it is difficult to achieve 100 percent dimensional accuracy, calibration grade slip gauges are not necessarily available in a set of preferred sizes but their sizes are up to the 3rd or 4th decimal place of a millimeter.

Slip Gauges Size

Slip gauges are available in standards of both metric and in inch units. If we talk about the metric units, slip gauges are available in the 31, 48, 56, and 103 pieces set.

Check prices at Amazon

Protection Slip Gauges

In a set of slip gauges, there is a pair of tungsten carbide protection gauges. These are available in 1 or 1.5 or 2 or 2.5 and mm thickness. These are marked with the letter ‘P’. These gauges are wrung to the end of slip gauge combination and are used along with the instruments like sine bars that are made of metallic surfaces and which can increase the wear of the regular slip gauges. The purpose of using of these wear blocks is that one at the top and the other at the bottom is to ensure major wear is concentrated over these two wear gauges that can be replaced economically. Hence the life of the set of slip gauges increased.

Wringing of Slip Gauges

When two flat and smooth surfaces are brought into close contact with each other then the phenomenon of adhesion of two flat and smooth surfaces is called Wringing. The force of adhesion is such that the different set of blocks which are joined serves as a single block.

Wringing Phenomenon

When two surfaces are brought into contact with each other then we know that there is some space exists between them. This is because of the irregularities in the surface and oil, dirt or Greece present on the surface. If we assume that two surfaces are perfectly highly finished and free from oil and dirt and are pressed together then the air gap is so small that it makes a liquid film. The thickness of this film might be as low as .00001 mm.

Procedure of Wringing of Slip Gauges

- First of all, slip gauges need to be cleaned carefully just before the wringing process.

- Then overlapping is to be done by 1/4th of their length

- After that, we need to slide 1 block perpendicular to the other with minimal pressure.

- Then we need to rotate one of the blocks till the time it is in line with the other block.

Slip Gauge Uses

Slip gauges have many benefits which are given below:

- These are used to measure the precise measurement where the accuracy of work demands it.

- To check the accuracy of other measuring instruments.

Slip Gauge Material

Tungsten Carbide

- Very hard

- Costlier

- Wear-resistant.

Chrome Plated

- Anticorrosive property

- If the gauge is worn out, can be done plating again

High-Grade Steel

- Hard

- Economical

Also, read about what is Arduino

What are Slip Gauges?

These slip gauges are rectangular blocks that provide a high degree of accuracy. These gauge blocks are also known as Johansson gauges.