Flow Control Valve, Types, Working, Parts

As the name suggests, a flow control valve is defined as the valve which is used to control the rate of flow through a hydraulic circuit. The main function of flow control valves is to increase or decrease the speed of actuators, for example, hydraulic cylinders or hydraulic motors. If there is no flow control valve in the circuit, then the actuators will run at high velocity and damage the job, which might cause an injury to the operator and machine.

In this article, we will learn about the functions, diagrams, working, and types of flow control valves.

Functions of Flow control Valve

The flow control valve has many functions and some of them are discussed below:

1. To Control the Speed

Flow control valves are used to control the speed of an actuator. We can increase or decrease the speed of actuators with the help of flow control valves. The velocity of the piston of the cylinder depends on the flow rate in the actuator and the area of the piston. Mathematically, it can be written as:

Velocity= Flow Rate/Area of the Piston

V= Q/A

Where ‘V’ is the velocity of the piston, ‘Q’ is the flow rate in the actuator and ‘A’ is the area of the piston

2. To Regulate the Power

Flow control valves regulate the power available to other subcircuits by controlling the flow. The power is dependent on the flow rate and pressure.

Mathematically, it can be written as:

Power= Flow rate x Pressure

P= Q x p

Where ‘P’ is power, ‘Q’ is the flow rate and ‘p’ is pressure.

3. To Regulate the Pump flow

It helps to transfer the set quantity of liquid to the different sections of the hydraulic circuit to manage multiple tasks.

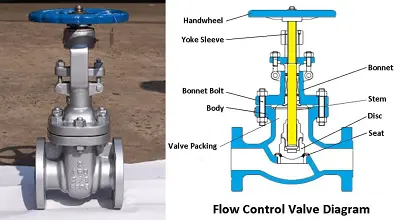

Components of Flow Control Valves

Now, first of all, we will get to know the basic parts of a flow control valve.

The flow control valve has the following parts:

- Body

- Bonnet

- Trim

- Disk and seat

- Stem

- Actuator

- Valve packing

We will discuss all of them one by one:

1.) Body

This is the body of the valves in which all the parts are assembled. we can also say that everything that has been attached to the framework is called the body. The body is sometimes also called a shell. It receives inlet and outlet piping through welded or bolted joints. Valve bodies are cast into many different shapes and sizes depending on their application. The body is basically made of cast iron.

2.) Bonnet

The bonnet is defined as the cover that is used for opening the valve body. Bonnet is different in different valves in some cases it might be the body itself that splits into the two sections that have bolted together. While in other cases it supports internal accessories such as an actuator, disc, and stem. It is cast or forged of the same material as the body and connected to the body by a threaded bolted or a welded joint.

3.) Trim

Valve trim is basically the internal elements of a flow control valve. It includes a disc, stem, sleeves, and seat. The performance of the valve is generally determined by the seat and the disc interface.

4.) Disk and Seat

This is an important part of the valve because it allows the fluid to flow if the valve is open and it restricts the flow if the wall is closed. So the disc should be made of hard material and it must have good wear characteristics.

5.) Stem

The stem is a part of the valve which helps to connect the actuator and the disc and is responsible for the positioning of the days. Stems are generally cast and connected to the disc by welded or threaded joints. There are two types of stems, one is called the rising stems and the second one is called the non-rising stems.

6.) Valve Actuator

Valve actuators are those parts that are used to operate the stem and the disk assembly. A valve can be operated manually by operating the handle, lever, and motor, by pneumatic or hydraulic means.

7. Valve Packing

Valve packing is a very important part of any flow control valve and is used to prevent the leakages because they are spaces between stem and bonnet and packing is used to prevent the leakage in that particular area. Packing is generally made of fibrous material or other compounds such as Teflon which is used to form a seal between the internal and the outside where the stem extended through the body.

If the packing is too loose, then it will cause leakage and if the packing is too tight, then it impairs the movement of the parts and damage the seal and other parts. So, proper tightening is necessary for packing in the flow control valve.

Working of Flow Control Valves

Many of the simplest flow control valves are having a hole or orifice which opens and closes in order to increase or decrease the flow rate. If the opening is large then the flow rate will be increased, and if the opening is smaller the flow rate will be decreased because there is lesser area to pass the flow of fluid through that particular area. Whenever fluid flow is controlled in a floc control valve then there is a pressure drop and this Pressure drop is need to be considered while the selection of the control valve.

In a hydraulic circuit, there are always fluctuations. Sometimes there are higher and sometimes there all smaller. In a hydraulic circuit, Inlet pressure is constant but outer pressure may be different. So to take care of these kind of fluctuations, there is pressure compensated flow control valves that can keep the flow rate at constant with the variable load.

Types of Flow Control Valves

Following are the types of flow control valves:

- Gate valve

- Plug valve

- Needle valve

- Non-return valve

- Butterfly valve

- Pressure compensated flow control valves

- Pinch valve

- Globe valve

- Diagram valve

- Ball valve

Use of Flow Control Valves in Circuits

Flow control plays a very important role in controlling the speed of the actuators in hydraulic circuits. On this basis, these can be classified as

- Meter-in Circuit

- Meter-Out Circuit

- Bleed-off circuit

Also, read What is Hydraulics and Hydraulic components