What are Nuts and Bolts | Types of Nuts and Bolts | Difference Between Nuts and Bolts

Nuts and bolts are the types of fasteners that are used to join or hold the two-piece together as a rigid attachment. Nuts and bolts are used to assemble and disassemble the parts or objects easily when required. We will discuss the types of bolts and nuts in detail in this article.

Let us Discuss Bolts

Bolts

Bolts are defined as threaded fasteners with a head at one end and body or thread at another end. Bolts are designed to insert in the holes and then it is tightened by the nuts by rotating the nuts on the threaded part of the bolts. Bolts can also be tightened by rotating the bolt head against the nut. For tightening of the bolts, we need tools like a ring spanner or Double end spanner, etc.

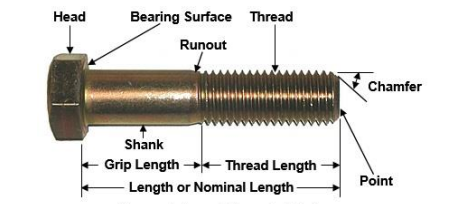

Parts of a Bolt

Let us discuss the parts of a bolt. Here the example of Hex bolt is given.

Head

The Head is the enlarged shape of the bolt and made at one end to provide a bearing surface and for turning the fastener.

Bearing Surface

The bearing surface is defined as the supporting surface for the part it fastens.

Length or Nominal Length

The length of a bolt is the total distance from the head(bearing surface) to the other side of the bolt as shown in the image given above. In the case of countersunk bolts, the length of the bolt is the total length of the bolt with a countersunk head.

Thread Length

The thread length of a bolt is the total length of the thread from one end to other.

Shank

Shank is that part of the bolt which lies between the head and starting point of the thread.

Chamfer

The chamfer is the conical surface at the starting end of the thread.

Material of Bolts

The most common type of material used for fasteners is steel. The grade of steel deepened on the application or the strength required. Bolts are also made of stainless steel, titanium, brass, plastic, etc.

Process of Making a Bolt

A summary of the production process:

- Wire – First of all wire is Uncoiled, straightened, and cut to the required length.

- Cold forging – Then, Mold the steel into the right shape at room temperature.

- Bolt head – After that, the bolt head is formed by forcing the steel into various dies at high pressure.

- Threading – Threads on the bolts are formed by rolling or cutting.

- Heat treatment – After the formation of thread, the bolt is then exposed to extreme heat to harden steel.

- Surface treatment – After the heat treatment process, zinc-plating is done to increase corrosion resistance.

- Packing/stocking – Lastly, after quality control, to ensure uniformity and consistency, the bolts are then packaged.

Types of Bolts

There are many types of bolts which we will discuss one by one.

Hex Bolts

Hex Bolts are the most common bolts used in industry. These hax bolts are fasteners which are having a head of hexagonal shape and an externally threaded body. These bolts are used with the hex nuts to assemble the two objects together. These hexagonal bolts are available in standard dimensional inch and metric sizes. Hex bolts are used to join metal to metal, wood to wood, or wood to metal parts. Hex bolts come in different shapes and sizes. Hex bolts are used with washers so that they will not get loose and proper tightening should be there.

U-Bolt

U-Bolts are those types of bolts which ar having the shape of a U and that are having male threads on each side of the bolt. These threads are partially threaded. These bolts are used to clamp the object at a place. These u shape bolts are used to support the piping, for example, supporting the exhaust pipe in a car. A bracket is placed in u-shape bolts and then nuts are tightened on both sides. Sometimes a gasket is placed between the u-shape clamp and object so that it should not wear due to the vibrations. A gasket might be of rubber or any other soft material.

Carriage Bolts

Carriage bolts are used to fasten the metal to metal or wood to metal or wood to wood. Carriage Bolt shape is such that it behaves like a self-locking screw. The shape of the carriage bolt head is a Mushroom type and has a shank of circular cross-section. These bolts are mostly used in carpentry and wood construction. Moreover, these bolts are used by homeowners and students for making DIY projects etc.

Lag Bolt

Lag bolts are heavy-duty fasteners and are mostly used in woodworking. These bolts make their own mating thread when tightened.

Eye-Bolts

Eye bolts are those bolts that have a threaded portion at one end and make a ring at another end. These eye bolts have a specific purpose. These are used in industrial applications. These are used to mount on the machine and ropes, chains, and shackles are secured by it. Then we can lift the machine or any equipment with the help of an eye bolt by a crane or Forklifter depending on the application. These eye bolts should be designed as per the weight of the machine which is given by the machine manufacturer. So, the safe working load needs to be checked before using the eye bolts.

Allen bolts or Socket Screw Bolts

Socket screw bolts are also known as Allen bolts. These bolts have a hexagonal socket in their head and are designed to use with the fallen wrench set. Allen bolts provide strong gripping.

Anchor Bolts

Anchor bolts are used to attach a structural component to the concrete slab or foundation. Anchor bolts may be preset in the place while the concrete structure is to be cast or anchor bolts may be attached after the concrete structure formation by drilling the concrete and putting the anchor bolts.

Elevator Bolts

Elevator bolts have a thin body and a round head. These elevator bolts are used in spaces where there is less space for example, in elevators and conveyors.

Flanged Bolts

Flanged bolts are those kinds of bolts that have a circular flange under their head and act as a washer and distribute the load. These bolts are also known as frame bolts. These bolts are fabricated from steel or stainless steel.

Square head Bolt

Square head bolts are having the head square means having four sides and are threaded to receive a nut. These square nuts are used in railway applications or to achieve an aesthetic traditional look.

Stud Bolt

Stud bolts have a thread on both sides of the bolt and it does not have any head. Nuts can be fastened from both sides.

Arbor Bolts

Arbor bolts are specially designed bolts. These bolts are not general that you can find in local hardware stores or in your plant. Arbor bolts have a washer permanently fixed at the tip of the bolt. These arbor bolts are specially designed for power tools. These tools hold the tool securely and keep the blade in its place. If you see an arbor bolt is loose, kindly do not operate the machine till the time it is tightened or replaced with a new one.

Countersunk Bolts

Countersunk bolts are flat head surfaces with a hex socket in the head. An Allen key is used to loose or tighten the bolts. These bolts are used so that bolts fit completely in the workpiece as per the pre-designed application.

Nuts

Nuts are the types of fasteners that are internally threaded and are used on the external threads mating parts like bolts and studs to assemble and disassemble two or more components.

Types of Nuts

There are many types of nuts that are used for specific purposes and some are used for general purposes. Different types of nuts are explained below:

Hex Nut

Hex nuts are of hexagonal shape and are the most common types of nuts having internal threads. These are used for fastening to hex bolts or socket cap screw.

Lock nut

Lock nuts are nuts that are used to prevent the loosening of bolts. Thes bolts come in various sizes and shapes. Lock nuts are also called self-locking nuts and these are widely used in the industry.

Coupling Nut

The coupling nut is a hexagonal-shaped nut and is used to connect the two male threads. Due to their hexagonal shape, these nuts are driven by wrentch.

Square nut

Square nuts are four-side nuts. These nuts provide greater surface contact preventing loosing of nut.

Wing Nut

Wing nuts are the nuts that are having wings on both sides the nuts that allow for manual tightening or loosening of nuts. It can be easily rotated by hands.

Castle Nut

Castle nuts also called slotted nuts are used with cotter pins to prevent loosening. These are used in low torque applications.

Frequently Asked questions

What is a Bolt?

Bolt is defined as threaded fasteners with a head at one end and body or thread at another end. Bolts are designed to insert in the holes and then it is tightened by the nuts by rotating the nuts on the threaded part of the bolts.

What is a Nut?

Nuts are the types of fasteners that are internally threaded and are used on the external threads mating parts like bolts and studs to assemble and disassemble two or more components.

What is the Difference between Nuts and Bolts?

There are many difference but the basic difference are as follow:

The nut is a type of fastener which is always used with the bolt and the bolt is a solid cylindrical fastener used with the nut. Nuts have internal threads and bolts have external threads.

Resources: itafasteners.com

Also, Read What are Different Types of Threads